Best innovations in Corrosion protective chemicals

Glaceon’s Corrosion Protective Chemicals are designed with advanced patented technology to enhance performance, fuel efficiency, and equipment life. These products help industries reduce emissions, prevent corrosion, and maintain long-term system reliability — even under high-temperature and high-stress environments.

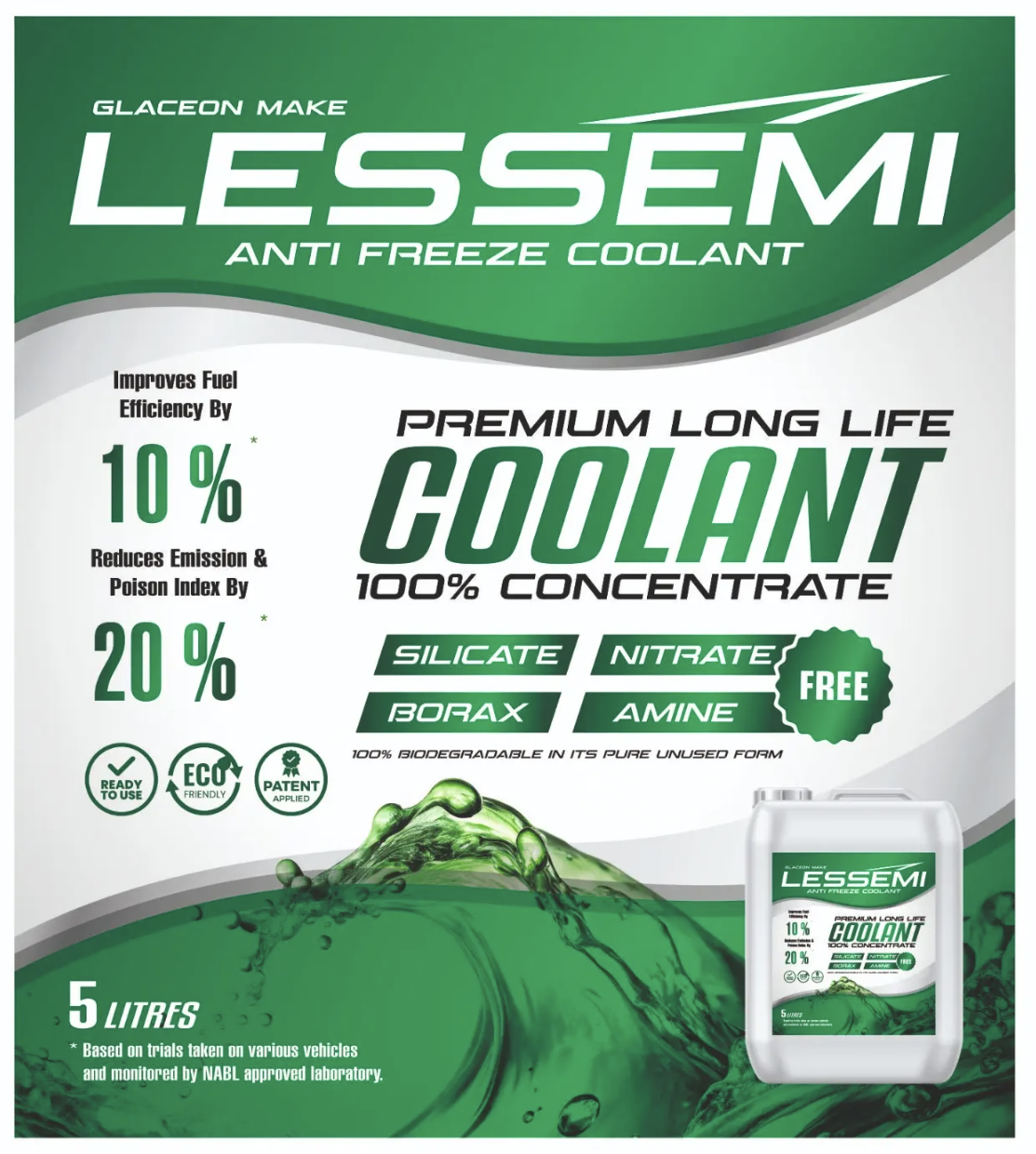

Our innovative coolant is formulated to optimize engine temperature, improve fuel efficiency, and reduce harmful emissions.

How It Works:

Conventional coolants often contain a high percentage of water that evaporates at elevated temperatures. This leads to the loss of inhibitors, scaling inside the system, and reduced heat transfer efficiency. The resulting overheating can create vapour in the pump system, causing pitting, reduced pumping capacity, and eventual engine stress.

Glaceon’s low-water, high-boiling-point coolant eliminates these challenges. It minimizes liquid loss, prevents vapour formation, and maintains consistent pumping and heat transfer performance throughout operation.

- Improved Engine Efficiency: Maintains optimal engine temperature for better fuel economy.

- Reduced Emissions: Supports complete combustion and minimizes pollutants like HC and CO.

- Anti-Scaling & Corrosion Protection: Prevents deposits that reduce cooling efficiency.

- Enhanced Engine Life: Protects against vapour lock, pump wear, and overheating cycles.

Surface Protectors – Long-Term Anti-Corrosion Technology

Glaceon’s Surface Protector is a synthetic, non-combustible, low-viscosity liquid developed with a patented blend of corrosion inhibitors. It is designed to protect and extend the life of internal components in submersible motors and other critical machinery.

Product Highlights:

- Corrosion Inhibition: Forms a durable protective film over metals such as iron, steel, copper, brass, and aluminum.

- Scale Prevention: Prevents scale formation, ensuring consistent operational efficiency.

Enhanced Lubrication: Reduces internal friction in bearings, gaskets, and seals to minimize wear. - Superior Heat Transfer: Keeps the system cooler for optimal performance.

- Stable & Long-Lasting: Offers extended protection and reliable chemical stability.

- Material Compatibility: Safe for both metallic and non-metallic components of submersible pumps.

- Eco-Friendly: Biodegradable and environmentally responsible formulation.

Applications:

- Automotive cooling systems

- Submersible and industrial motors

- Heat exchangers and closed-loop systems

- Pumps, valves, and metal components exposed to moisture or high temperature

Questions? You’re covered

We’ve answered some of the most common queries to help you better understand our products, applications, and services. From technical specifications to ordering and support, find all the information you need right here.

Paint driers are additives that speed up the drying and curing of paints, coatings, and varnishes.

They reduce drying time, improve surface hardness, and ensure a smooth, durable finish.

We supply Cobalt, Manganese, Zirconium, Calcium, and customized blends for different applications.

The choice depends on your paint system, finish requirements, and drying speed. Our experts can guide you.

Yes, our formulations comply with international safety and environmental standards.

Have Questions? We’re Here to Help!

Our team is always ready to provide expert guidance and support. Whether you need product details, technical specifications, or tailored solutions, we’re just a click away.